Imagine a smartphone that charges completely in 5 minutes and lasts a full 10 hours before running on empty. Crazy, right? Toting along the charging cord is just another part of life with 4G streaming and a power-hungry screen.

Back in January, Motorola’s Droid Razr Maxx offered the first real glimmer of hope for long-life batteries with the 3,300mAh ticker that dwarfed the battery in any other available handset — it ran for 19 hours in CNET’s tests, a longevity that hasn’t been reproduced since.

That leaves the question I get asked over and over again: why is it taking so long for batteries to catch up to all the other advances in smartphone technology?

There’s good news and bad news. The good news is, help is on the way. The bad news is, much of the cutting-edge development is still a year or two out. Here’s a look at some of the exciting evolutions, and even revolutions, coming to the stuff that fuels our smartphones.

Now playing:

Watch this:

Inside the guts of a battery factory

3:06

Smartphone batteries today: Two ways to get more yield

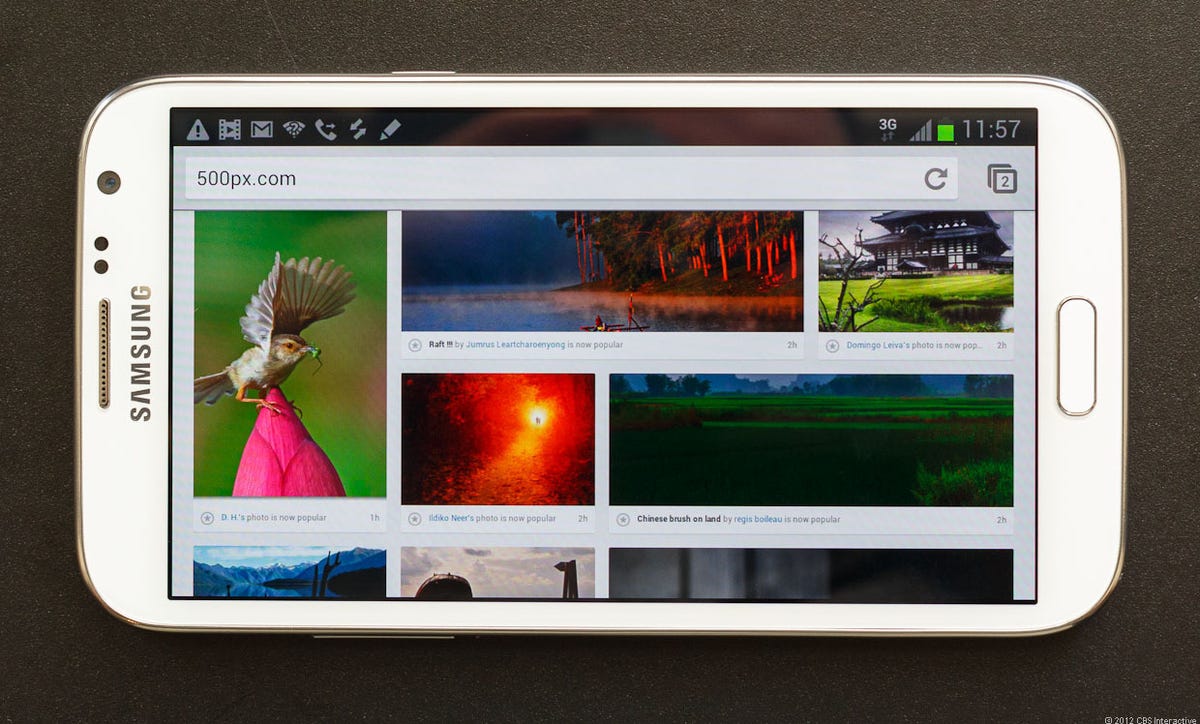

Right now, all smartphones use rechargeable lithium ion batteries. One trick to eke out longer battery life is to simply pack in a larger battery, as with the Samsung Galaxy Note 2 (3,100mAh battery.) However, those oversize screens need more power to shine brightly.

A second tactic is to use embedded (read: nonremovable) batteries in phones, like HTC’s One X, Motorola’s Droid Razr phones, and every Apple iPhone. Embedded batteries can take on any dimension and nook within the phone’s guts. They also require less packaging, which gives phone makers more leeway to increase the battery’s size.

These methods help suck more power out of every brick, but researchers are working on more radical change. Before they charge ahead, there are several problems that get in the way.

Stephen Shankland/CNET

Problem: Users are abusers

Use a phone to make a couple of calls or the occasional text, and it’ll last for days on a single charge. Use it as your data center, communications hub, and entertainment nexus, and you’re looking at a nightly recharge.

Streaming music and videos gobbles up the most battery, but so does downloading and uploading apps, photos, and status updates. Searching for Wi-Fi and GPS signal demands power, as does lighting up the screen. Apps that update in the background are also culprits (especially with this glitch.)

Problem: Chemistry is chemistry

Part of the problem comes down to the periodic table, and scientists’ challenge to use the same elements in novel ways.

Jessica Dolcourt/CNET

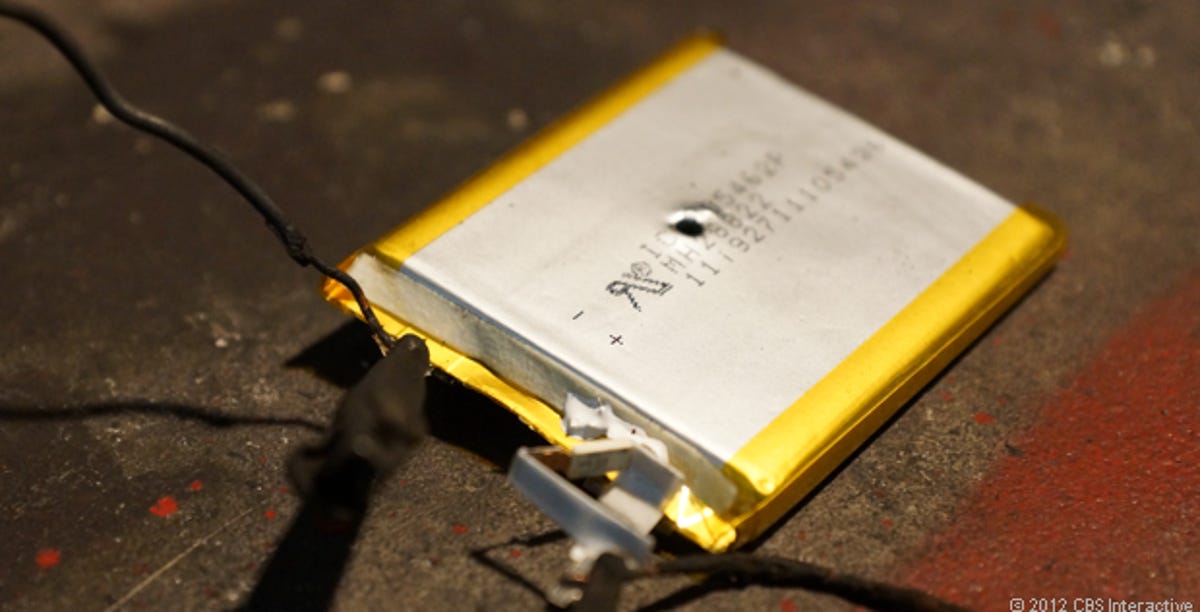

There are only so many chemicals you can use to create a battery, and there are fewer combinations that are stable enough not to erupt when damaged. Lithium ion batteries are used in smaller consumer electronics because of their comparatively high power yield and relative safety.

Solution: The stuff inside

Tucked into a business park in a nondescript section of Fremont, Calif., researchers at Leyden Energy are working to increase battery life by concentrating on the stuff inside of the battery.

Basic battery structure is fairly straightforward, which makes redesigning them a challenge. Lithium ion batteries have two electrodes — an anode and a cathode — and an electrolyte material in between that carries the ions from one electrode to the other to complete the charge or discharge.

Here in Leyden Energy’s cleanroom facility, technicians develop and test batteries made with a specialized solution that promise to last 10 percent longer per charge.

Leyden’s electrolyte material uses lithium imide as the electrolyte salt, a compound that keeps the chemicals inside more stable, especially when the battery reaches higher temperatures. All devices heat up — 104 F/40 C is the average internal temperature — and a spinning, straining processor can ratchet up the degrees.

Hot devices also cause the battery to swell and exacerbates the production of hydrofluoric acid, a toxic by-product that degrades batteries over time. The argument of “thermal resilience,” keeping internal temperatures cooler, is Leyden’s central benefit.

Jessica Dolcourt/CNET

As a result, Leyden says its batteries have a longer lifespan than today’s lithium ion batteries, between 750 and 800 charging cycles until the battery hits 80 percent of its original capacity, versus the 350-to-500-cycle average of regular lithium ion batteries. All told, Leyden promises up to three times the cycle life of a battery, and triple the calendar life, depending on how long the battery could sit in a warm warehouse before it’s shipped out in a device.

Although Leyden’s patent-protected imide salts don’t have the same boom-pow factor as a silicon anode (described below), there’s the added benefit that Leyden’s batteries keep the same form factor and assembly line as ever.

“It’s tough to come across a solution that works with your existing technology…at a similar cost,” ABI analyst Michael Morgan said about Leyden. “All that doesn’t come together very often.” With Leyden’s design, “you just swap out the goo that goes in the middle.”

Leyden’s design will cost a little more than today’s batteries, and is about 18 months from appearing in the mass market. In June, chip-maker Nvidia and Leyden partnered up to put Leyden’s battery in a Tegra 3 tablet reference design. If Nvidia’s partners, like Asus for example, like what they see, they could commit to making the tablet, battery and all.

Solution: Get with silicon

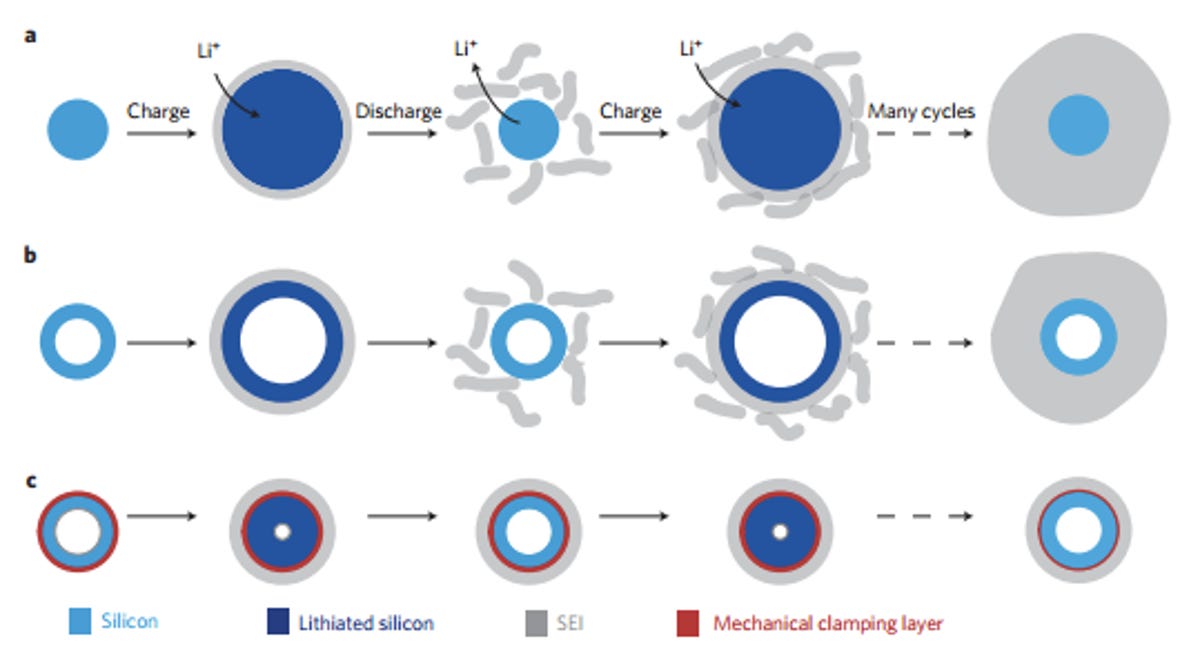

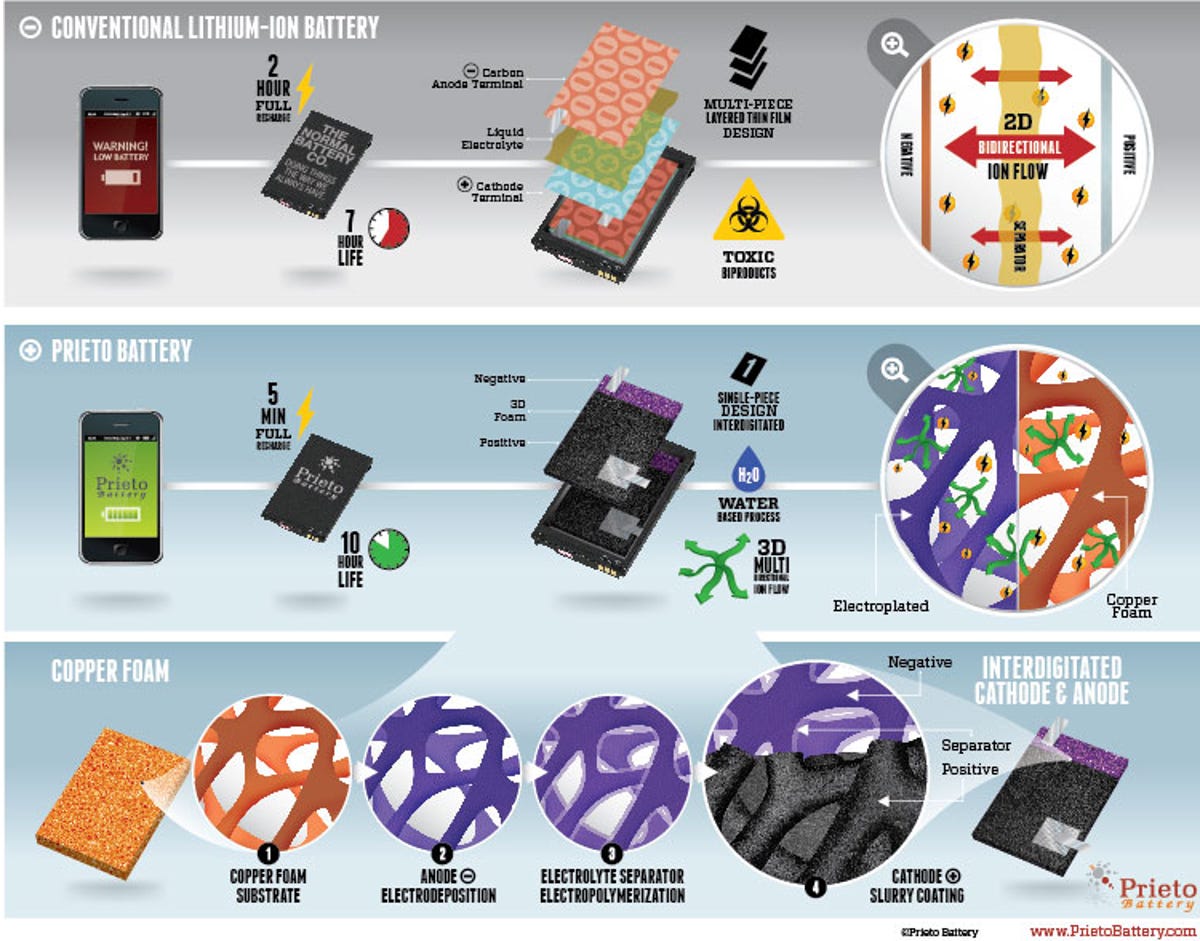

Many researchers have a crush on silicon as the solution to better battery life, specifically making anodes out of the stuff, and for good reason. You can cram up to 10 times more ions into silicon than the traditional graphite. There was just one major drawback: silicon anodes quickly swelled and then cracked, deteriorating the battery. Oops.

It was back to the drawing board for Stanford University professor Yi Cui, who has since engineered a double-walled silicon structure that uses a tough outer wall like a belt to keep an inner silicon sanctum from overexpanding.

Jessica Dolcourt/CNET

Stanford’s research team claims that its silicon-headed lithium ion batteries last for 6,000 charging cycles before reaching 85 percent of the battery’s original capacity. This 80 percent or 85 percent mark is an industry standard when talking about the calendar life of a battery; in other words, when it’s time to replace it.

Like a lot of researchers, Cui uses nanotechnology to build his silicon anode. The larger surface area creates a higher number of sites for power-creating reactions. A nanostructure also lets Cui fashion “anti-space,” which he says leaves room for materials to expand without breaking the whole.

In addition, shrinking the component parts helps fashion a battery that’s lighter and smaller than the standard lithium ion bundle, but retains the same energy density. Smaller, more-powerful batteries can affect the phone’s eventual design and can also create room for other elements: perhaps a larger camera module or maybe even a second battery.

Cui’s company, Amprius, hopes to see his high-power nanostructure batteries in tablets, smartphones, laptops, and electric vehicles in another two years.

“Silicon is low-cost by itself, and we are developing the manufacturing process right now for these types of structures,” Cui told me over the phone. “Materials like silicon can create a huge impact to the smartphone industry.”

Yi Cui

Solution: Think tin

Researchers out of Washington State University are also on the quest to replace the traditional graphite anode with another electrode substance. This time, tin.

Lead researcher Grant Norton and his team report findings that a tin anode can almost triple the capacity of the lithium ion battery’s usual graphite head. True, the battery wouldn’t be as powerful as silicon’s potential, but it also isn’t as short-lived as those earlier experiments.

The team’s tin method uses electroplating, a process that binds metal to another surface (in this case, copper). Norton claims that the tin anode would not just last longer but also cost less to build than graphite anodes. Since the rest of the battery would look the same as what you already have in your phone, the design should appeal to device makers. Likewise, the electroplating process is used often in manufacturing and wouldn’t necessarily require machining new tools.

Solution: Make it 3D

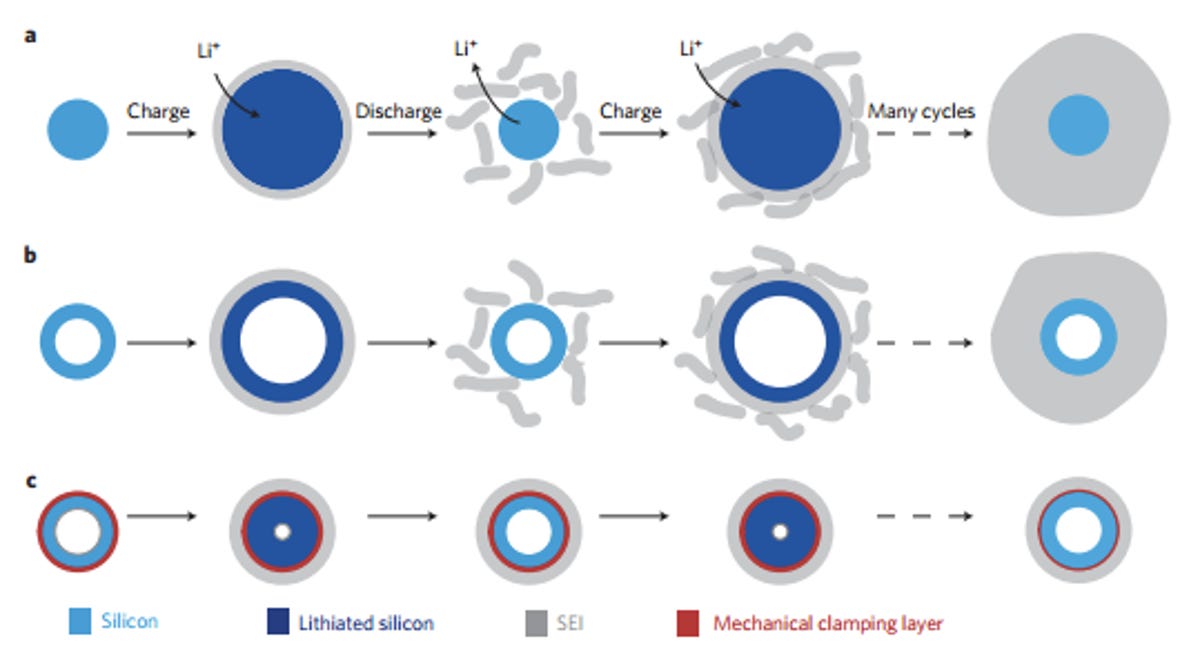

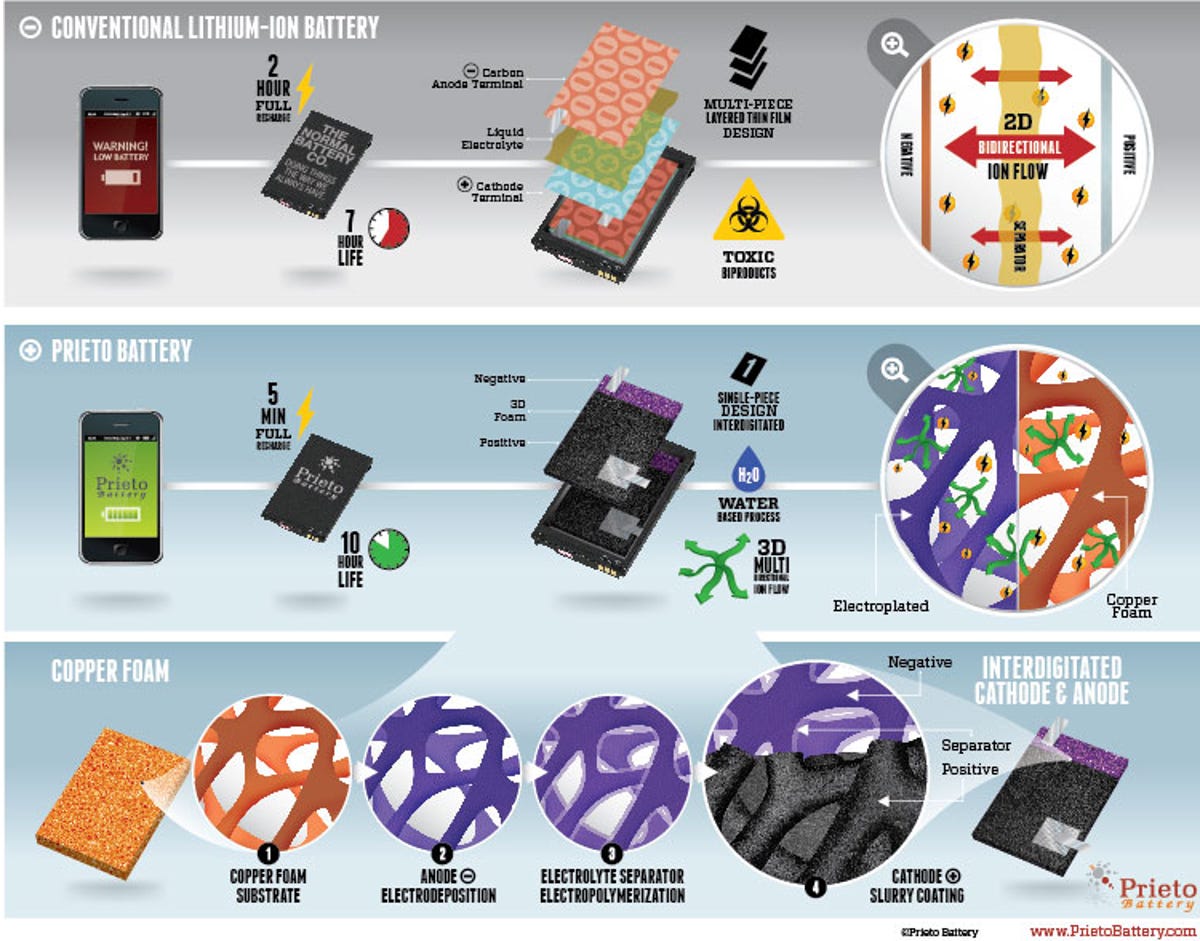

Much battery R&D focuses on improving one part of the creation process, but Amy Prieto has much more radical plans. The company she founded, Prieto Battery, is giving the entire power cell a makeover.

Prieto reimagines the lithium ion battery in a 3D solid-state form, with no liquid electrolyte at all. Instead, copper foam (first generation) or a nanowire structure (second generation) forms the backbone, with the anode, cathode, and electrolyte material all coated on top using a similar electroplating process as the tin solution above.

The foam or spun nanowire is important because it increases the surface area for the lithium ion movement to take place; the shorter distances between the components means that charges generate very quickly — theoretically 5 minutes for a complete charge. The arrangement keeps the anode and electrolyte in constant contact, which also speeds up reactions.

Prieto Battery

The anode in a Prieto battery is different, too. Instead of graphite, Prieto uses copper antimonide, a compound that stores more lithium per unit of volume than graphite does. All told, a Prieto battery is projected to last 10 full hours and completely charge in 5 minutes. An early prototype made with slightly different materials lasted 750 charging cycles before dropping to 80 percent of the total charge capacity. The final battery blueprint calculates that a Prieto battery will last 30 percent longer than a conventional battery.

As with the other three fixes to the battery life problem, Prieto batteries are still in development, but Prieto looks to commercialization in 18 months after it licenses the patent-pending architecture to other manufacturers.

It turns out that Prieto is also a bit of a Captain Planet, emphasizing that a Prieto battery doesn’t call for clean rooms and the only acid it uses is citric. “You can dump it down a sink,” Prieto told me, “and it’s really cheap.”

Using off-the-shelf manufacturing equipment and steps that make more power cells on a given production line will help cut manufacturing costs.

The road ahead

A battery that can go the distance isn’t just about leaving the charger at home for a day or two; it’s also about creating smarter smartphones. More-powerful batteries can support far more-complex computing and gaming tasks; create a GPS beacon; work with a greater number of peripheral devices like medical equipment; and support resource-demanding artificial intelligence like Siri and other assistants.

A long-life battery can open the doors to carry the smartphone to the next step of being a truly personal, portable electronic powerhouse.

Smartphones Unlocked is a monthly column that dives deep into the inner workings of your trusty smartphone.

Read more Smartphones Unlocked

- 5 things you didn’t know about data testing

- The near future of smartphones

- HD Super AMOLED versus Retina Display, and other screens

- Camera megapixels: Why more isn’t always better

- 7 myths about quad-core phones

- The birth of a cell phone

Josh Long/CNET