Dong Ngo/CNET

LAS VEGAS — You’ll soon be able to print your own refrigerator magnets and more.

MakerBot announced Tuesday here at the 2015 International CES that it’s using new PLA Composite Filaments made with composites of real metal, stone and wood. Basically, these materials, in powder form, are mixed with regular PLA filament to create a new special type of filament. As the result, the printed objects will provide more of the look and certain characteristics of the materials being used.

For example, an object printed using metal PLA filament can be magnetized and is heavier than the same object printed using regular pure-plastic PLA filaments.

MakerBot showcased samples of objects printed using the new type of filaments and they indeed looked very realistic. A 3D-printed hammer looked just like a regular hammer and in fact can be used as a hammer for light hammering jobs.

Dong Ngo/CNET

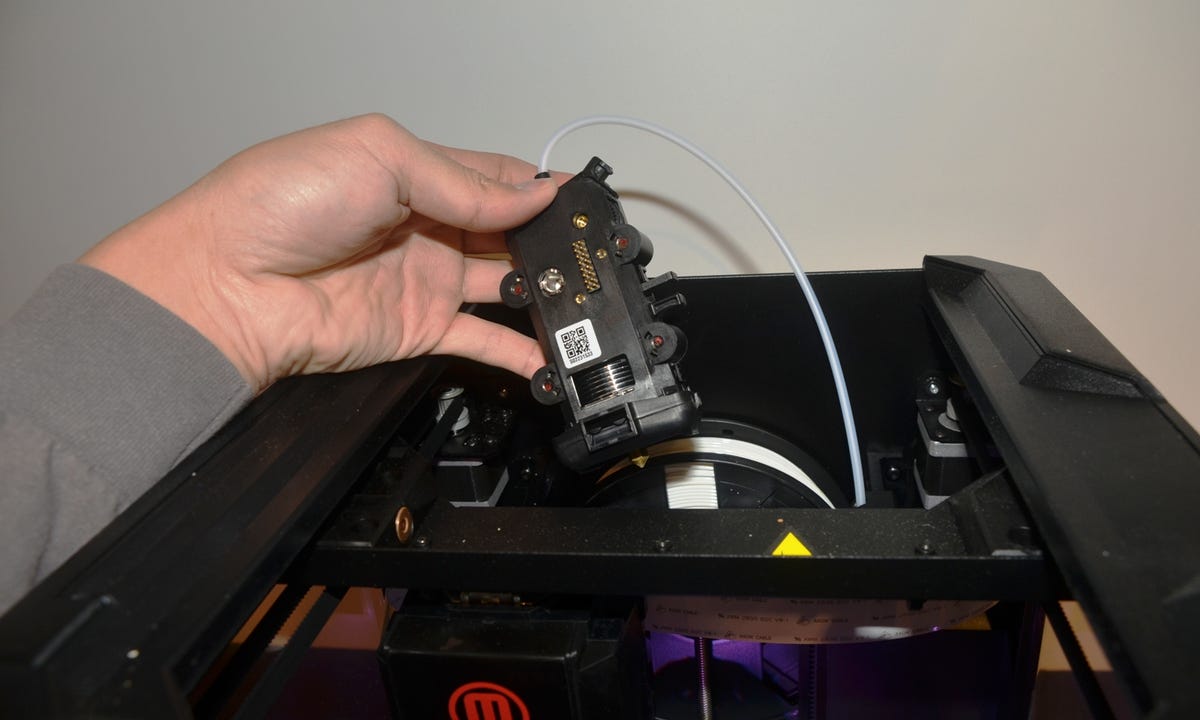

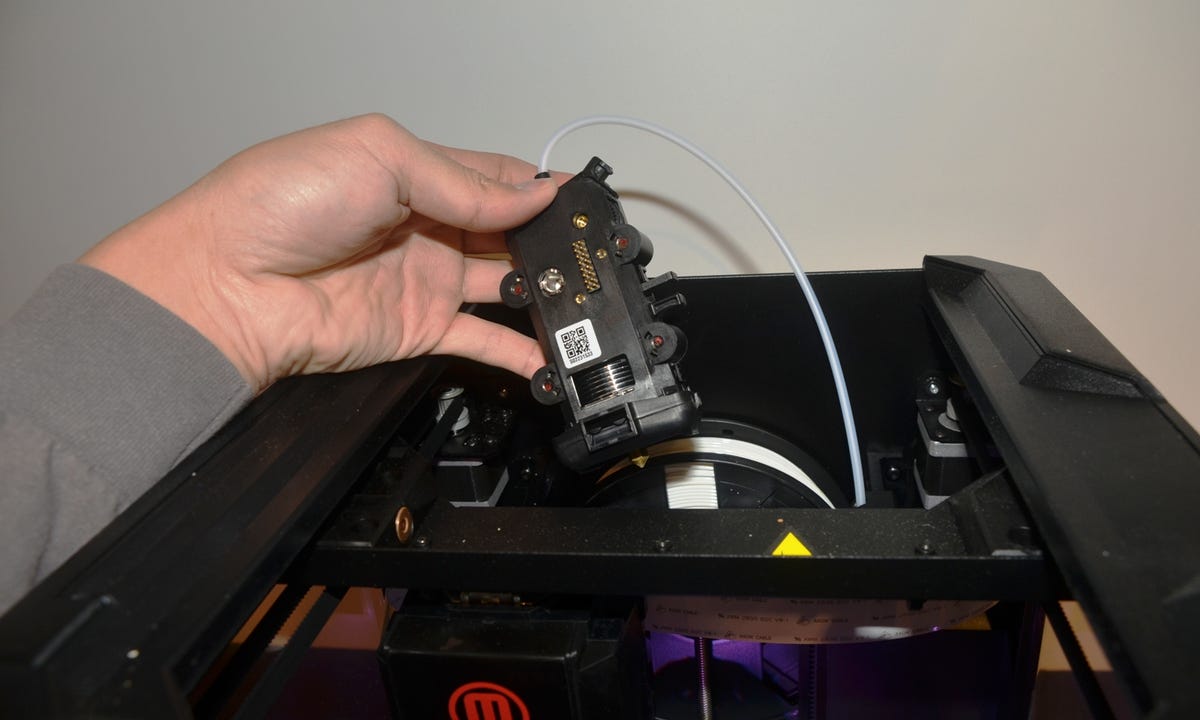

In order to print the new materials, however, a new extruder is needed for each material type. The good news is all MakerBot’s fifth-generation 3D printers support a Smart Extruder, which can be easily swapped out.

All the cool new gadgets at CES 2015 (pictures)

The company says it’s working on making these extruders and expects to ship them in the second part of 2015. In the meantime, it’s planning to include a Mobile True Remote Monitoring feature in its latest 3D printer. This feature, set to be available in early 2015, makes possible remote monitoring of 3D print jobs via Wi-Fi or cell signal. Since a print job can last for hours, this will be a very helpful feature to have.

And finally, the company announced a new MakerBot 3D Professional Services division that aims to brings the company’s expertise in 3D printing to customers. The MakerBot 3D Professional Services are available now, with consultation, customer education, 3D design services, 3D printing services and an innovation/management platform. Information is available on MakerBot’s website.

Now playing:

Watch this:

New directions in 3D printing

19:42