Check Also

The US Is About to Exit a Long Dark Age of Lousy Headlights

[dzs_video source=”https://cnet.redvideo.io/2022/09/16/49769be8-2384-4b14-9e21-dd7391f645d1/adaptive-headlights-4kfinal_720h3200k.mp4″ cover=”https://www.cnet.com/a/img/resize/ddcd07e4d9afd5a49c8fdd756e1fb3514818d952/hub/2022/09/16/eeb958f1-4ba5-41ed-9dee-49607cb78be6/mazda-i-activsense-adaptive-led-headlamps-alh-mp4-00-01-04-10-still001.jpg?auto=webp&fit=cover&height=482&width=856″ config=”skinauroradefault” width=”100%” height=”600″ logo=”https://joggingvideo.com/wp-content/uploads/tdn_pic_2.png” config=”skinauroradefault” autoplay=”off” cue=”on” loop=”off” type=”video” logo=”0000″ logo_link=”5555″ responsive_ratio=”default” …

3D

Check Also

The US Is About to Exit a Long Dark Age of Lousy Headlights

[dzs_video source=”https://cnet.redvideo.io/2022/09/16/49769be8-2384-4b14-9e21-dd7391f645d1/adaptive-headlights-4kfinal_720h3200k.mp4″ cover=”https://www.cnet.com/a/img/resize/ddcd07e4d9afd5a49c8fdd756e1fb3514818d952/hub/2022/09/16/eeb958f1-4ba5-41ed-9dee-49607cb78be6/mazda-i-activsense-adaptive-led-headlamps-alh-mp4-00-01-04-10-still001.jpg?auto=webp&fit=cover&height=482&width=856″ config=”skinauroradefault” width=”100%” height=”600″ logo=”https://joggingvideo.com/wp-content/uploads/tdn_pic_2.png” config=”skinauroradefault” autoplay=”off” cue=”on” loop=”off” type=”video” logo=”0000″ logo_link=”5555″ responsive_ratio=”default” …

3D

Check Also

The US Is About to Exit a Long Dark Age of Lousy Headlights

[dzs_video source=”https://cnet.redvideo.io/2022/09/16/49769be8-2384-4b14-9e21-dd7391f645d1/adaptive-headlights-4kfinal_720h3200k.mp4″ cover=”https://www.cnet.com/a/img/resize/ddcd07e4d9afd5a49c8fdd756e1fb3514818d952/hub/2022/09/16/eeb958f1-4ba5-41ed-9dee-49607cb78be6/mazda-i-activsense-adaptive-led-headlamps-alh-mp4-00-01-04-10-still001.jpg?auto=webp&fit=cover&height=482&width=856″ config=”skinauroradefault” width=”100%” height=”600″ logo=”https://joggingvideo.com/wp-content/uploads/tdn_pic_2.png” config=”skinauroradefault” autoplay=”off” cue=”on” loop=”off” type=”video” logo=”0000″ logo_link=”5555″ responsive_ratio=”default” …

3D

Check Also

The US Is About to Exit a Long Dark Age of Lousy Headlights

[dzs_video source=”https://cnet.redvideo.io/2022/09/16/49769be8-2384-4b14-9e21-dd7391f645d1/adaptive-headlights-4kfinal_720h3200k.mp4″ cover=”https://www.cnet.com/a/img/resize/ddcd07e4d9afd5a49c8fdd756e1fb3514818d952/hub/2022/09/16/eeb958f1-4ba5-41ed-9dee-49607cb78be6/mazda-i-activsense-adaptive-led-headlamps-alh-mp4-00-01-04-10-still001.jpg?auto=webp&fit=cover&height=482&width=856″ config=”skinauroradefault” width=”100%” height=”600″ logo=”https://joggingvideo.com/wp-content/uploads/tdn_pic_2.png” config=”skinauroradefault” autoplay=”off” cue=”on” loop=”off” type=”video” logo=”0000″ logo_link=”5555″ responsive_ratio=”default” …

3D

Most 3D-printed objects aren’t exactly cuddly. They tend to be made of hard plastic. Researchers at Carnegie Mellon University, however, can print model horses with braidable tails, troll heads with brushable hair and wizards with long, lush beards.

The concept for 3D-printing hair was inspired by those tiny strands you get when you pull a hot-glue gun away from a gob of melted plastic. The same idea works for the plastic used by a 3D printer. “You just squirt a little bit of material and pull away,” said Gierad Laput, a Ph.D. student in Carnegie Mellon’s Human-Computer Interaction Institute.

Laput and his colleagues refer to this as “furbrication.”

Related stories

- Injured toucan gets beak repair courtesy of 3D printing

- World’s tiniest circular saw 3D-printed into improbable existence

- Coffee-based filament turns java into brown 3D-printed objects

Printing hair “requires no special hardware, just a set of parameters that can be added to a 3D-print job,” Carnegie Mellon notes. The printer used for the experiments cost just $300 (about £196. AU$423). Each strand of hair is made by instructing the printer to create a tiny blob of molten plastic and then pull the print head and print bed off to the side, drawing the plastic out into a thin filament.

The finished hair can be trimmed, braided, brushed or curled. It’s conceivable that a printer could turn out an entire human-size wig, but the process is slow. It takes nearly half an hour to make plastic hair for an area just 10 square millimeters in size.

The world of 3D printing has expanded considerably in recent years. Disney Research developed a method for 3D-printing fabric objects like teddy bears. An injured toucan got a beak repair with the help of a 3D-printed prosthesis. The ability to print combable hair onto plastic objects opens up opportunities for makers to get even more creative with their models. Just wait for this method to be used on a 3D-printed Chewbacca toy.

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

Enlarge Image

Enlarge ImageVideo screenshot by Amanda Kooser/CNET

The Loom Launcher’s promo video on Kickstarter starts off in a suitably dramatic fashion, with designer Adrian van Wijk intoning about how the creation is “the first all-in-one, mechanical, 3D-printed, multi-shot rubber band launcher with a self-priming trigger.” Then it ascends into cat footage and childlike excitement about the project.

Toy rubber band guns have been around about as long as rubber bands themselves. I had one crafted from a curled piece of wood when I was a child. Kids (and adults) today can have toys made of much more modern materials like the 3D-printed nylon used by Loom Launcher.

Related stories

- Injured toucan gets beak repair courtesy of 3D printing

- World’s tiniest circular saw 3D-printed into improbable existence

- Coffee-based filament turns java into brown 3D-printed objects

The Loom Launcher line consists of four different gun designs and two magic wands. The guns are small and printed in white, so they do look like toys. The magic wands, however, are a lot more fun. Since we can’t really be Harry Potter with a working magic wand, this is the next best thing. It can’t cast a spell, but it can cast a rubber band.

The Wizard wand has a lightning-bolt design on it and is made to look like a sculpted branch. Harry Potter fans will be all over this model. You will need to shout something like “Flexilis cohortis!” every time you fire it. The Princess wand opts for a leaf and star pattern and would look great with a custom glitter paint job.

All of the Loom Launcher toys have the capacity to hold 12 mini rubber bands at a time, a distinct advantage over the slow-loading forefinger-and-thumb hand model most rubber-band warriors start out with. The range maxes out at about 20 feet (6 meters).

One nice thing about a 3D-printed project like this is that you can just buy the DIY files for the classic gun style for a mere $5 (about £3, AU$7) pledge and make your own (if you have access to a 3D printer). The wand files cost $12 (about £8, AU$17). If you want Loom Launcher to print one and send it to you, it starts at a $28 (about £18, AU$39) pledge.

Keep in mind that not all crowdfunding projects deliver as expected and on time. The Loom Launcher has already handily topped its $2,271 funding goal and has attracted over $8,000 with a few days left to run. Rubber-band warfare may never be the same again.

Loom Launcher

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

Enlarge Image

Enlarge ImagePhilipp Schmitt

Now that pictures of pretty much everything are available online, how many new shots of the Eiffel Tower do we really need? A new 3D-printed iPhone camera case — the Camera Restricta — will stop you from taking photos at traditional tourist traps in hopes that you’ll go out and find something more original.

The Camera Restricta was created by German design student Philipp Schmitt, and it looks similar to old-school point-and-shoot cameras. The device uses your phone’s GPS and a custom Web app to pull location information from pictures publicly posted to Flickr and Panoramio to determine how many online pictures were geotagged at your location.

If too many pictures have been shot nearby (dozens, according to the video below), the shutter will retract into the case and the viewfinder will close, leaving you unable to take a picture until you go somewhere else. The shutter is powered by a microcontroller and some electronics built into the 3D-printed case.

Related Links

- Bear selfies force a Colorado park to close

- Selfie-taking tourists allegedly smash ancient Hercules statue

- Two women, desperate for original selfie, carve initials into Rome’s Colosseum

Camera Restricta provides feedback in two ways. The back of the device will physically display both how many pictures have been taken in a location and a bright yes or no (or nein!) as to whether photos are allowed at that location. The device also emits a static noise similar to a Geiger counter representing how many pictures are nearby. The more noise you hear, the less likely you’ll be able to take a picture in a given spot.

Schmitt hopes the product will result in people venturing beyond the typical tourist destinations and capturing unique pictures in relatively undiscovered places. He’s not offering the Camera Restricta as a product available for purchase, but he’s made the code fueling the project open source and available on GitHub so anyone who likes the idea can build upon his tech.

All told, Camera Restricta is a provocative project that challenges people to think more critically about the types of places they visit and photograph while on vacation. Perhaps, then, instead of adding to the 5 billion or so pictures of the Arc de Triomphe, for example, tourists will shoot France’s lesser-explored sights.

Would you use such a service if it ever came to market either as a smartphone case or an app that restricts pictures in popular locations? Let us know in the comments section below.

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

Enlarge Image

Enlarge ImageMrPrezident/Hackaday

What sort of Skittles eater are you? Do you like to carefully select according to the colour of the moment? Do you like to eat all the Skittles of each colour, in order of enjoyment? Or do you only eat one flavour, and give the rest away?

Whichever of these floats your boat, a recent project by Hackaday user MrPrezident (Nathan Peterson) will take out all the hard work of Skittle-sorting. The maker and engineer has designed and built a 3D-printed machine that is capable of sorting the candy by colour.

“I started working on this project because I thought it would be a fun project as it has some unique challenges, and it gave me the chance to make heavy use of my newly acquired 3D printer,” MrPrezident said on the Hackaday 3D-Printed Skittles Sorting Machine project page. “I wanted to build a compact machine that would sort skittles accurately and quickly.”

The machine runs on an Arduino Uno board, and uses a TCS3200 programmable colour sensor to detect the colours of the Skittles. A small LED attached to the colour sorting module, fitted with a polarising filter to reduce glare, ensures that the sensor is obtaining an accurate colour reading.

Related articles

- Epic hacker projects compete for a trip to space

- Thor’s hammer gets a Tesla coil, puts out 80,000 volts

- Most mind-blowing Lego creations

Once the colour of a Skittle has been identified, it gets dropped into the rotating sorter, which spins around and releases the Skittle into the appropriate dish. This is powered by three DC motors with gearboxes, with additional sensors to detect the positions of the discs and when a Skittle has been dropped so that the machine can continue sorting.

As you watch the machine at work, you’ll notice a few Skittles in the sorter that don’t get dropped into the dishes. These are the calibration Skittles, which allows the machine to recalibrate every time it starts. It also allows any type of Skittle to be sorted.

It’s probably not the best idea to try it on M&M’s, though.

“Technically this machine will sort of work with M&Ms, but not as well because M&Ms are a bit smaller and get jammed easier,” MrPrezident noted. “Also M&Ms have six colours, and this Machine is only designed to sort five.”

The full schematics, including the source code and 3D files, are available via the project page on Hackaday.

That’s going to free up a lot of Skittle-eatin’ time.

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

Enlarge Image

Enlarge ImageThe 3D-printed Maze hairbrush has sections that flex forward and backward to make hair removal a snap.

Scott Shim

When I see my wife cleaning her hairbrush, I get depressed and think, “I remember when I had hair.”

When Scott Shim, associate professor of design at Ohio State University, saw his wife undertaking the task, it got him thinking about ease and sustainability.

“I couldn’t understand why she had to do that. Obviously, this is not a problem for me,” Shim said in a statement Monday, referring to his own balding head. “Then I did some market research, and found out how often hairbrushes get thrown out — not because they’re worn out, but because they’re disgusting and people didn’t maintain them well.”

Shim’s research found that the longest people are willing to put up with a hairbrush entwined with hair, skin cells and and styling products is six months to a year. After that, they toss it.

So in an effort to keep all those hairbrushes out of landfills, and to make life a little easier for the full-head-of-hair-havers among us, Shim and former graduate student Morris Koo invented — and then 3D-printed — what they dubbed the “Maze hairbrush.” It gets its name because the paddle part of the brush looks a bit like a maze with individual sections that flex forward and backward to make removing hair a cinch.

Related stories

- Stem cell-grown hair could help those with hair loss

- ‘Game of Thrones’ superfans want Kit Harington to cut his hair (spoilers)

- Clandestinely control your smartphone by stroking your hair

“Our goal was for the user to easily remove hair from the bristles,” Shim said. “We latched on to this idea that brushes usually have a solid surface that gets in the way of cleaning. We decided that the best solution would be to create a brush with an open surface, where the user could actually open it and just grab the hair.”

Currently, Shim and Koo are making prototypes by 3D-printing the brush bases one at a time and then inserting the bristles by hand. The bristles have proven to be tricky, because the printer they’re using can only output brittle bristles, which sometimes snap when they’re put in place. But the duo hopes to change that. They’re currently looking for strong, flexible plastics that will suit mass production, and hope to collaborate with materials scientists on the product, according to Ohio State.

With that problem solved, mass production will hopefully follow. A rollout of the patented hairbrush seems likely as it’s already won two awards — first place in the beauty, personal care and cosmetic products category in Italy’s A’ Design Awards and a Green Product Award from White Lobster, a German agency for sustainable innovation.

(Via 3Ders.org)

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

Enlarge Image

Enlarge ImageFathom

Medical casts are getting a whole lot smarter thanks to the BoomCast, a 3D-printed cast with sensors and electronics onboard to help doctors better track the healing process and provide improved mobility.

The BoomCast project was conceived of by Mike North, perhaps best known for his role on the Science Channel’s “Outrageous Acts of Science” or his “In The Making” YouTube series. North broke his leg celebrating the life of his best friend Dan Fredinburg, the Google executive who was killed in an avalanche on Mount Everest back in April.

When North, a frequent traveler who’s highly active, was fitted for a cast, his doctors gave him two options. Either he could be fitted with a walking cast that allowed him to move freely but not be able to travel due to potential swelling, or they could cut the cast in half to eliminate swelling issues, but he’d be bound to crutches.

Fathom

Neither option sounded pleasant to North, so he turned to the folks at Fathom Studio, a 3D-printing and additive-manufacturing company, for help. Over the course of a couple of days, the Fathom team took a scan of North’s leg and created a so-called BoomCast custom-fitted to his leg that would allow him to travel and bear weight.

Of course, this was no ordinary cast, and North and the Fathom crew equipped the BoomCast with a host of sensors, lights and speakers to gather data and promote healing. The BoomCast is equipped with the Intel Edison chipset — a postage stamp-sized processor geared toward the maker and Internet of Things markets — which gives the cast its computational prowess.

The sensors feeding the Edison include a gyroscope, accelerometer, magnetometer and a few integrated pressure sensors, which combine to measure things like North’s leg movements and how much his leg is swelling. Data collected are fed to Google’s Firebase in real-time, where they can be shared with North’s doctor, who can use this information to provide better care to his patient.

Related Links

- Tears of joy: 3D printing lets blind mom-to-be ‘see’ her son

- Simple but ingenious invention takes the ouch out of injections

- Invention lets newborns in incubators feel mom’s heartbeat

- 3D-printed cast uses ultrasound to speed healing

In addition to providing protection and transmitting data, BoomCast also serves as a sort of entertainment device. The makers fitted BoomCast with Bluetooth speakers that were intended to provide sonic healing functionality, but North ended up using them to crank out some tunes to elevate his mood — something he says his friend Dan would probably do as well.

Don’t expect to see the BoomCast become a consumer product anytime soon, however, as it’s more a proof of concept that these types of things are possible in devices like medical casts. The team has made the project open-source — meaning that all of the information and designs the team use is available for others to take to create new, better products in the future.

With these advancements and others, it’s only a matter of time before casts and other medical devices get a whole lot smarter. Be sure to check out the video below to see how the BoomCast was designed and built, and visit Fathom’s page for even more info on the project.

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

Screenshot by Michelle Starr/CNET

Some people are passionate about coffee. Others about books, movies or games. There are, to paraphrase a certain timeless tale, as many passions as there are people. Dieter Michael Krone’s passion is paper aeroplanes.

The Düsseldorf-based mechanical engineer is one of the world’s leading authorities on the art of folding paper to make it glide. He has written a book on the subject. He has given a university lecture. He has an extensive website which lists the best materials for building paper aeroplanes; a history of paper aeroplanes; an essay on the physics of paper aeroplane flight; and, of course, a number of instruction sets for paper aeroplanes of his own design.

And, it turns out, he’s also something of a mad genius, as detailed on his YouTube channel. There, you can find a paper aeroplane made out of a burger box, an exploration about whether a paper aeroplane can carry an egg, paper aeroplanes that can embed themselves into a dartboard, and this magnificent creation.

Dubbed the A6 v1.0, it’s a 3D-printed thing of beauty. Like a printer, it holds a stock of paper which, one by one, it folds into a paper plane, then shoots into the air.

“A little tinkering from me that shows what you can do with 3D printers today. Most parts of this paper airplane machine gun had printed by fabberhouse.de (the rest of them are to buy via Internet or hardware store),” Krone wrote in the video description. “By the way, I use a cordless screwdriver from China for driving.”

He hasn’t listed specifications for printing your own anywhere on his website that we could see, or indeed any further information about its construction, but one thing’s for sure: if he were to put this thing on Kickstarter, we’d be there in a heartbeat.

Check Also

The M2 MacBook Air Is the Ultimate Laptop Gift

This story is part of 84 Days of Holiday, a collection that helps you find …

3D

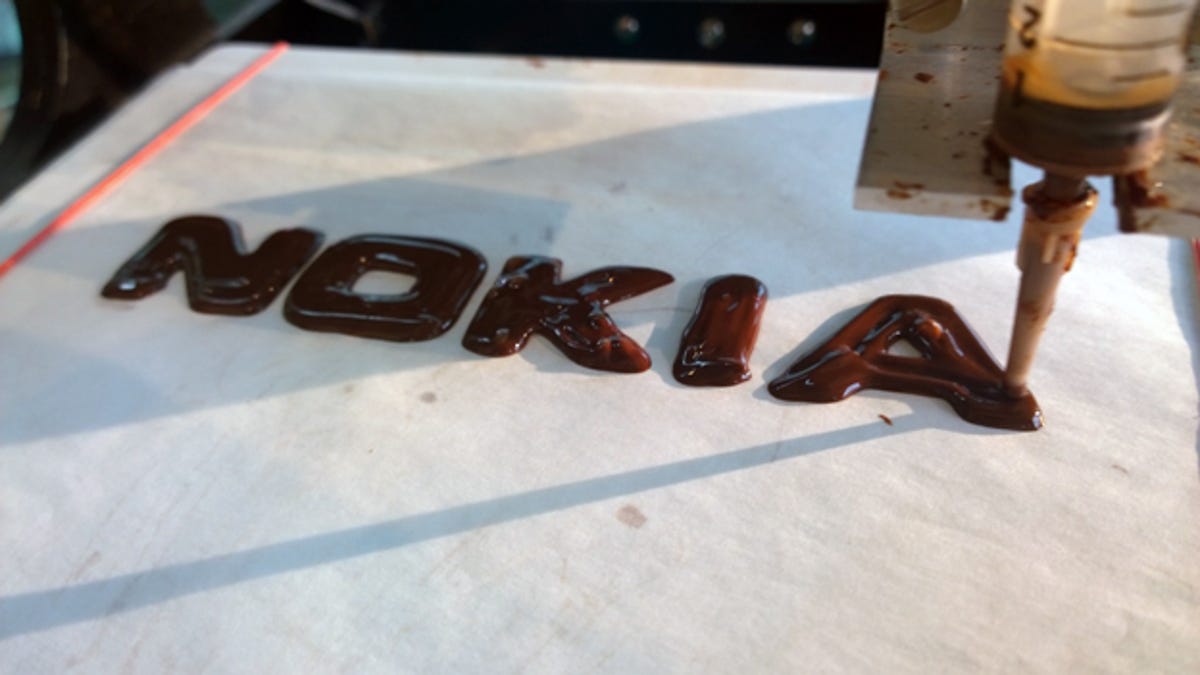

Nokia

Nokia has combined 3D printing and Easter to create a new, sweet rendering of its logo.

The company on Thursday published a YouTube video showing how it used software to render a 3D version of its logo, which was then transmitted to a 3D printer. The 3D printer was outfitted with liquid chocolate and created what the company is calling “#Chokia.”

3D printing has become the next big thing in new technology. Companies around the globe are investing heavily in 3D printing and prices on the devices are coming down to such a level that they’ve become affordable for some consumers. With 3D printers, users can create real-life models of, well, anything. Everything from guns to prosthetic limbs and even jet parts have been created with 3D printers thus far.

Nokia estimates that its chocolate logo weighs 30 grams and is 164 calories.

Here’s the video of the chocolate creation in action:

Check Also

8 New Google Products We Expect to See This Year

Google’s device line could end up having a particularly important moment in 2023. The company …