-

Featured Video

The Formlabs Form 2 is more than an expensive 3D…

The Formlabs Form 2 is more than an expensive 3D printer3:10 /

Feb 2, 2016

-

Playlist

-

The XYZPrinting Da Vinci Jr. 3D printer is not junior…

The XYZPrinting Da Vinci Jr. 3D printer is not junior at all3:35

Apr 23, 2015

-

The Cube 3 is a cute 3D printer to say the least

3:28

Feb 5, 2015

-

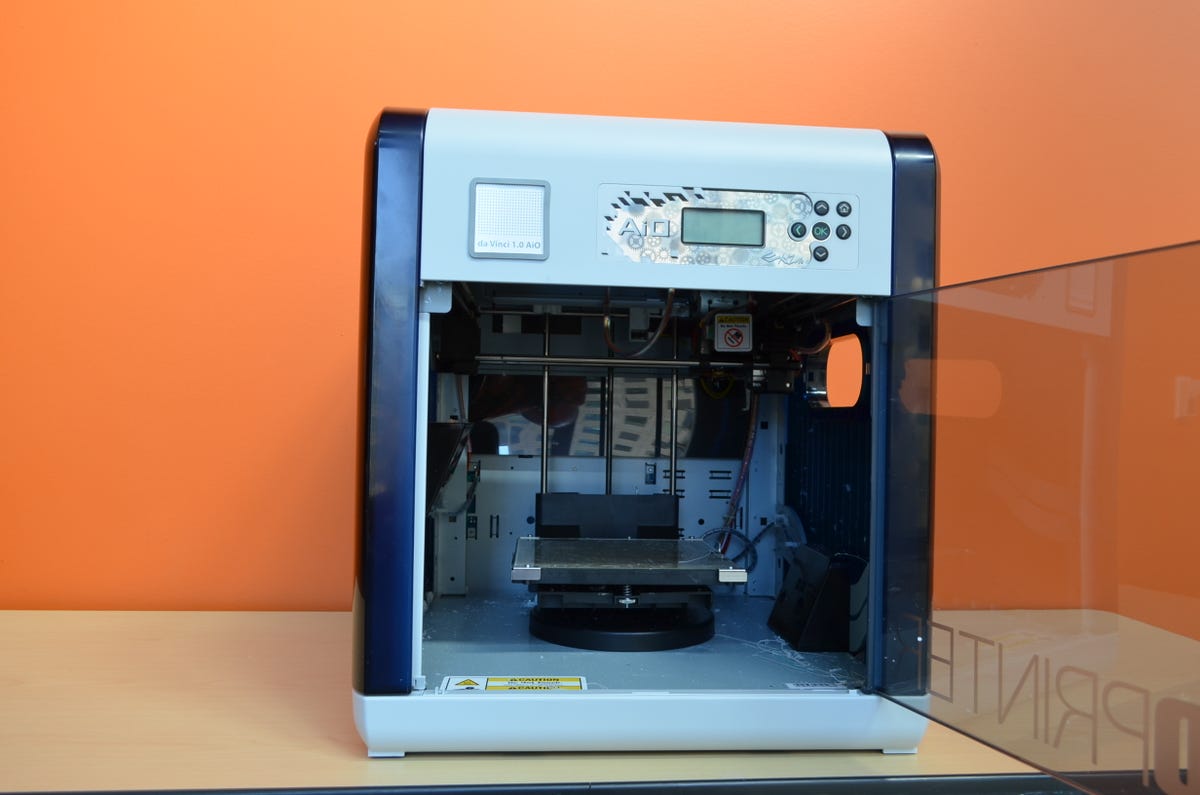

The XYZPrinting da Vinci 1.0 AiO is an affordable…

The XYZPrinting da Vinci 1.0 AiO is an affordable approach to 3D printing3:00

Nov 3, 2014

-

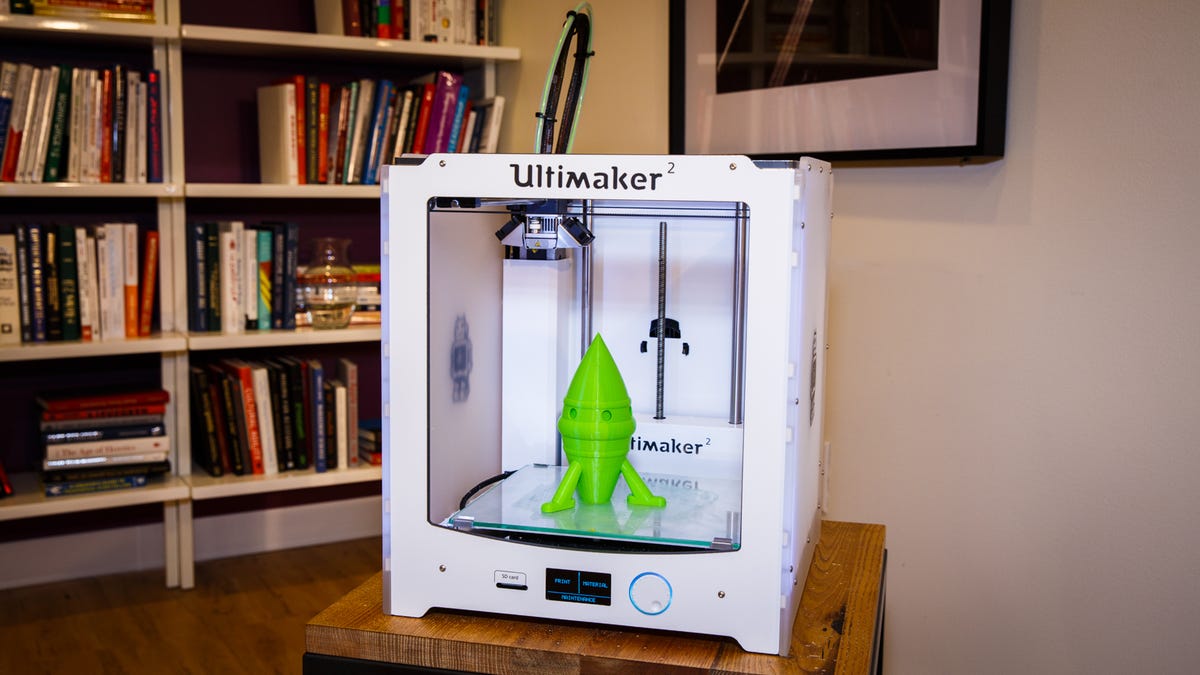

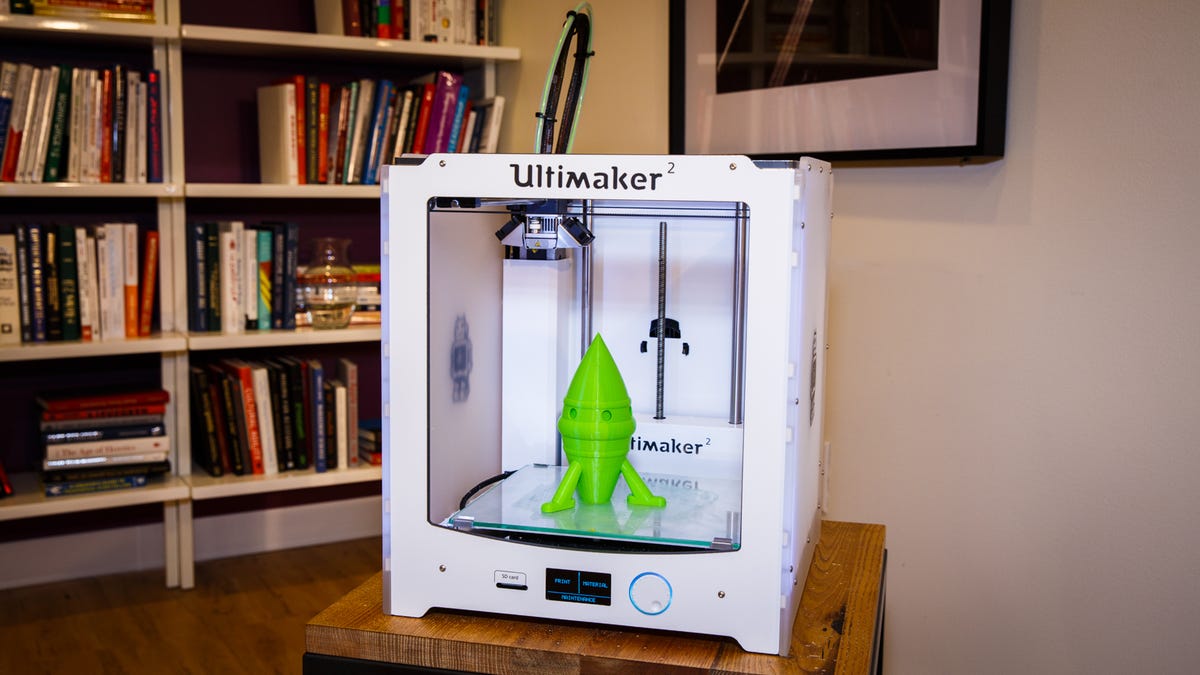

The Ultimaker 2 is a really good 3D printer that…

The Ultimaker 2 is a really good 3D printer that costs too much3:23

Dec 5, 2014

If you have something unique to make, especially one that’s complex, the fastest way to create it is a 3D printer.

So what’s 3D printing? Basically, it’s a process of synthesizing a three-dimensional object. A 3D printer is a machine that builds 3D objects according to a 3D model file. There are many 3D printing technologies but for consumers, currently only two are used. They are fused filament fabrication (FFF) and stereo-lithography (SLA), which are completely different from each other.

Fuse filament fabrication 3D-printing technology

Sometimes called fused deposition modeling (FDM), fuse filament fabrication (FFF) is the most popular and affordable 3D-printing technology. How it works is very similar to icing a cake, caulking a bathtub, though much more sophisticated.

In a nutshell, the printer melts material and extrudes it onto a surface in the shape of a 3D object and then wait for it to congeal. The material is called filaments. They are basically easily melting and fast-congealing plastic strings that normally come in spools. The surface is the build platform, the size of which determines how large a 3D object you can print. And finally, the print head, also known as the extruder, will do the actual job of building the 3D object. A printer’s print head may have just one nozzle (called a single-extruder) or two nozzles (dual-extruder). The former can print from just one spool of filament at a time, while the latter can handle two and allows you to print objects in two colors.

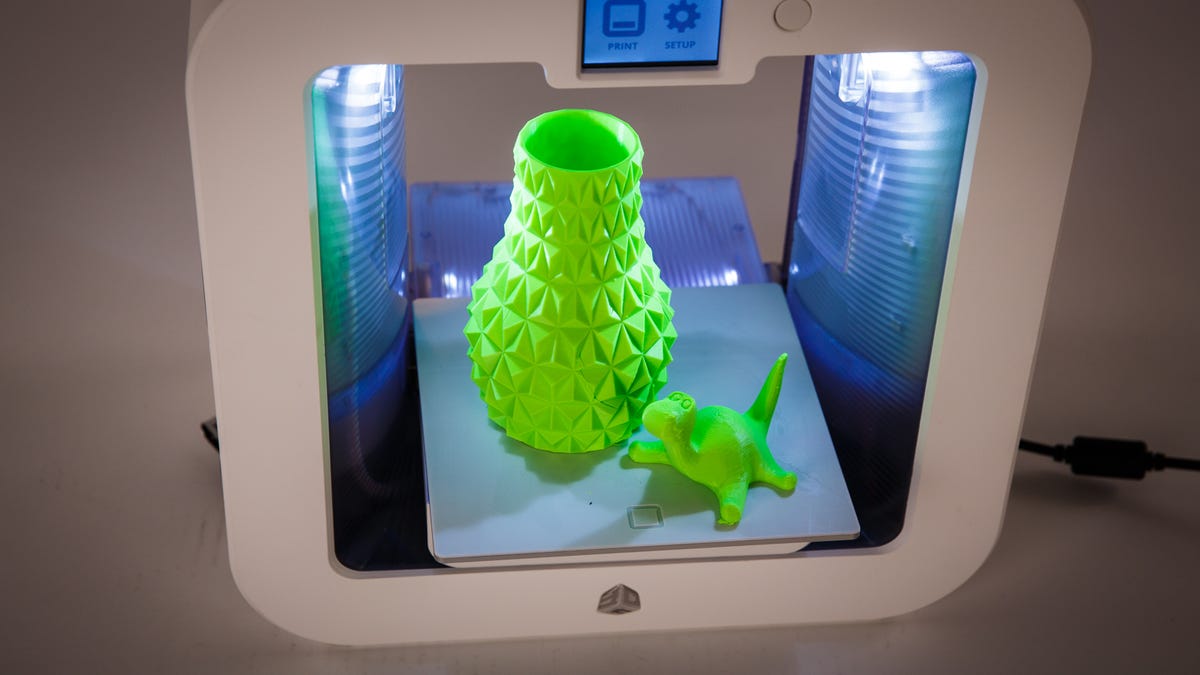

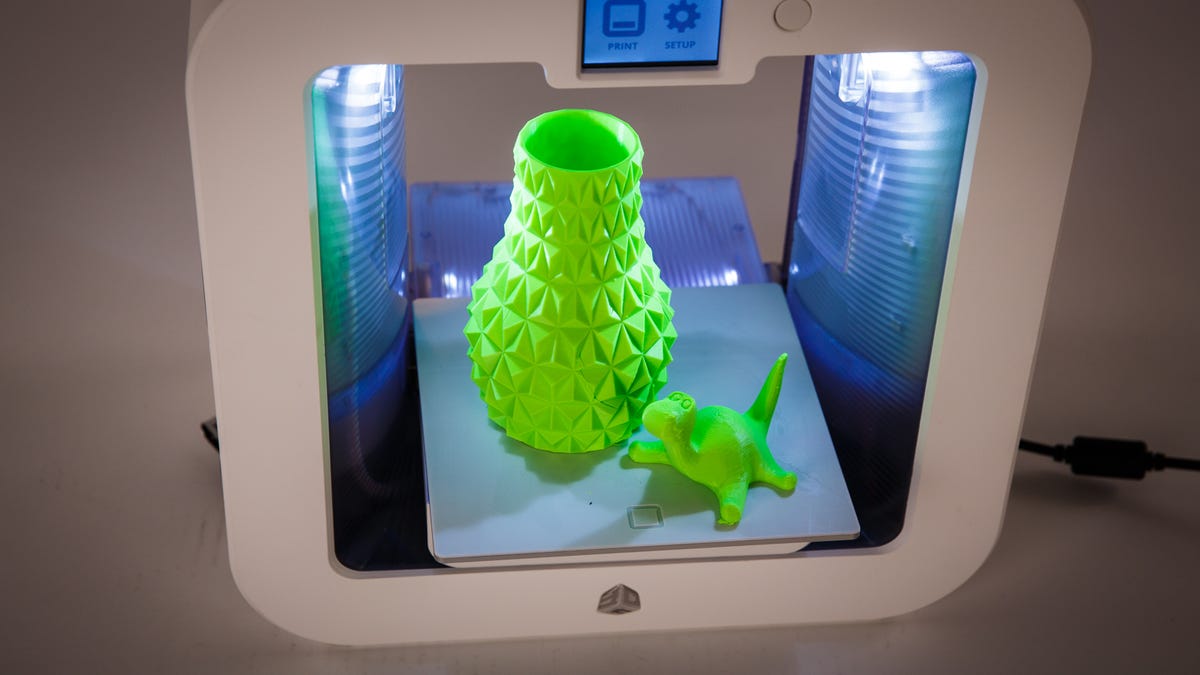

Enlarge Image

Enlarge ImageSamples of objects printed by FFF 3D printers.

Dong Ngo/CNET

During a print job, the print head pulls the filament string from the spool, melts the plastic, and extrudes it onto the platform. The platform lowers gradually depending on the height, while the print head moves around corresponding to the width and shape of the object being built. As the extruded plastic collects on the platform layer by layer, it congeals almost instantly to gradually form the object.

As you can imagine, for the 3D printer to work accurately, the build platform needs to be at a consistent distance, neither too close nor too far from the print head above it. Some printers require you to adjust this yourself in a process called calibration (also known as alignment or leveling); other printers can do this themselves or ship precalibrated. In my experience, manually calibrating a 3D printer can be a tricky and time-consuming process. This is the biggest hurdle you’ll need to overcome when first entering the world of FFF 3D printing. Fortunately, in most cases, you’ll just need to do this once and some printers can perform the calibration on its own.

Stereo-lithography 3D-printing technology

The SLA 3D printing technology works in the opposite way from fuse filament fabrication. This is because its print material is a form of liquid called resin. During a print job, the printer first pumps resin from a container (cartridge) into a glass tank at the bottom of the printer. After that the print platform, located on top, dips itself into the tank and slowly pulls up a solid 3D object, upside-down.

Enlarge Image

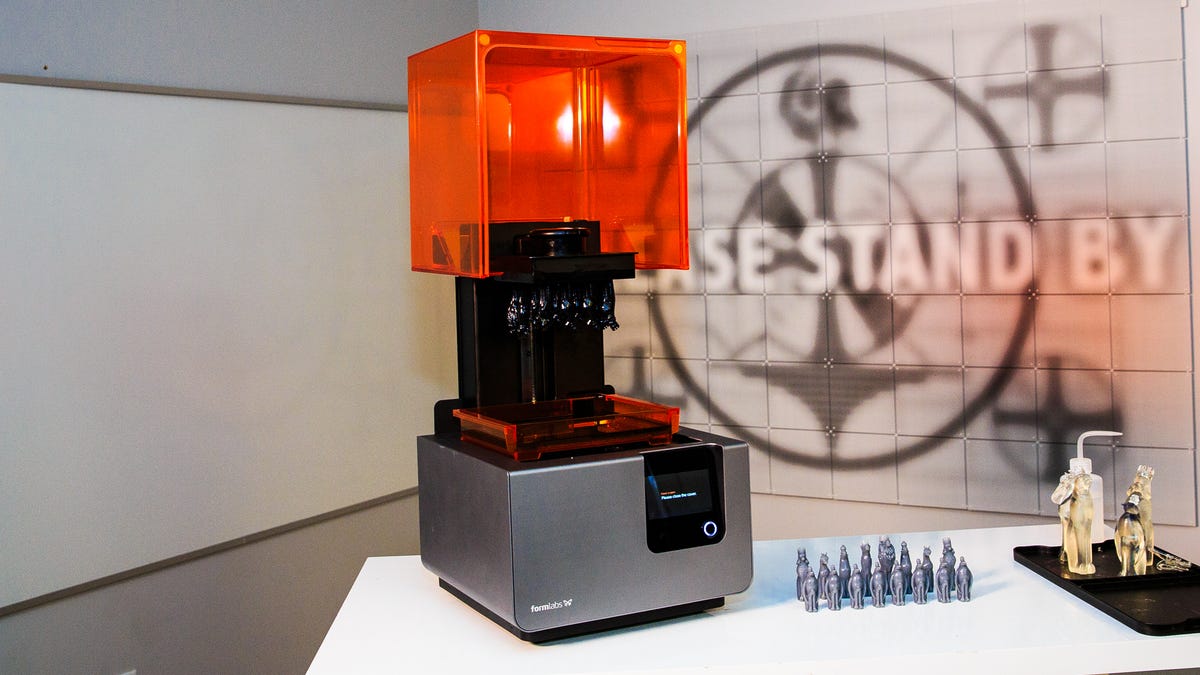

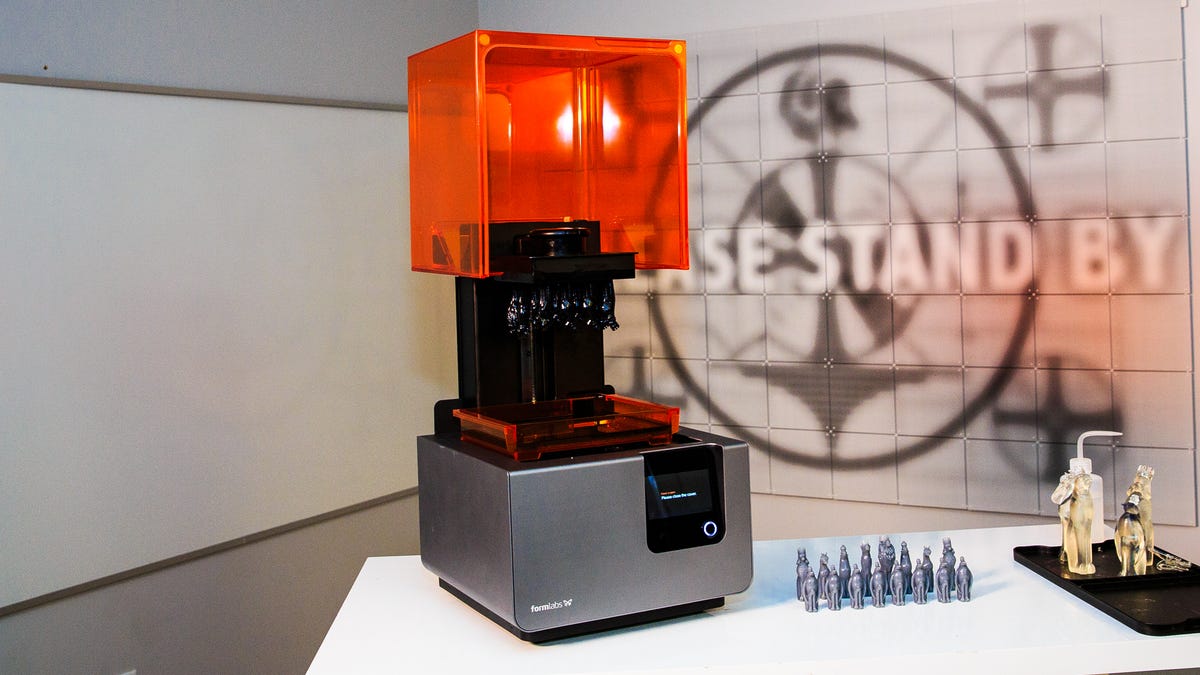

Enlarge ImageSamples of objects printed by an SLA 3D printer.

Josh Miller/CNET

More specifically, as the print platform lowers itself into the resin tank, an ultraviolet laser light, from underneath the see-through tank, shines on it. (For this reason, SLA is sometimes called the laser 3D-printing technology.) Exposed to the laser light, the resin cures, solidifies and sticks to the platform. As more resin is exposed to the laser light, the pattern is created and joins the layer above. As more and more layers are being created, the build platform slowly — very slowly — moves upward, finally pulling the entire object out of the tank as the print process is finished.

Another big difference between FFF and SLA 3D printing is that, while FFF produces a lot of heat during a print job (which is required to melt the plastic filament), SLA remains cool the whole time. Instead, you have to deal with the sticky resin, which can be messy. Also, while an FFF 3D object is ready to be used as soon as it’s through printing, an SLA 3D object needs to be washed with strong solvent (75 percent or higher alcohol) afterward; otherwise, it will remain wet (and sticky) for weeks. Furthermore, the way an SLA printer works means there will always be a noticeable amount of material left in the resin tank after each print. This means, if you don’t print frequently, the residual resin will go to waste.

In return, SLA printers generally create objects with significantly higher details than those made by FFF printers.

Print speed

No matter which 3D printer you use, be it an FFF or a SLA, the print speed remains the same: very slow. On average, it takes about an hour and half to print a simple iPhone 6S case. Larger and more complicated objects can take tens of hours to print. Keep in mind that while FFF printer can hollow out the thick parts (hence cut down the print time and the amount of material needed), SLA printers can’t. They always print in solid form. That said, if you want to print a large and round object (such as a puppy or a ball) that could take days to complete.

That said, if you think about making something you can buy, getting a 3D printer makes no sense at all, financially or practically. For example you can drive to the store and buy an iPhone case for just a fraction of the printer’s cost (not to mention the cost of filament) and in even less time than it takes to print one yourself.

But 3D printing is not about making everyday objects; it’s also about being creative and making things that are not readily available. And watching what you intend to create being meticulously realized in real time, albeit very slowly, can be very fun and satisfying.

As for what to print, you can get yourself a 3D scanner, create your own model with special software or just visit Thingiverse.com,where 3D enthusiasts exchange their 3D models. Many 3D printer vendors have their own 3D-model designing community.

With that in mind, here are five 3D printers that I have reviewed, listed by personal choice.

Josh Miller/CNET

Formlabs Form 2

The Form 2 is the only SLA 3D printer on this list and it’s the best 3D printer I’ve used so far. This is mostly the printer works very well and can deliver extremely high quality prints. It’s also very easy to use and comes with a Finish Kit for after-print cleanup. Furthermore, it supports many types of materials, including regular, tough, castable and flexible.

Like all other 3D printers, though, it’s slow, the small chest piece set in the picture, for example, took some 20 hours to finish. If you really have use for a machine like this, however, still, it’s totally worth the cost of $3,500 (£2,400 and AU$5,000.)

Read the full review of the Formlabs Form 2.

Josh Miller/CNET

XYZprinting Da Vinci Jr.

The single-extruder Da Vinci Jr. is currently by far the most affordable 3D printer on the market. At just $349 (£299), it’s about half the price of the next least inexpensive printer and just one-fifth the price of most 3D printers. But don’t let the low price fool you: this is also one of the most well-designed, easy-to-use 3D printers on the market. The machine doesn’t require manual calibration, it’s ready to work right out of the box, and it can print quite quickly with great details. It also works quite reliably in my testing. In all, if you can live with its modest build-platform size of 5.9 by 5.9 by 5.9 inches (150 by 150 by 150mm), this is a steal compared to the other 3D printers on the market.

Read the full review of the XYZprinting Da Vinci Jr.

Josh Miller/CNET

Cube 3

The Cube 3 — short for third-generation Cube — is the most compact dual-extruder printer I’ve seen, and also one that’s quite easy to use, though not at the level of the Da Vinci Jr. above. The printer is well-designed, it’s strongly built with an excellent mechanism and can print small objects with fine detail. It’s capable of printing fairly large objects, too. However, in my testing, some objects that might take 10 hours or more to print would fail halfway through.

At a cost of just $999 (which converts to £656 and AU$1,285), however, it’s one of the most affordable dual-extruder printers on the market.

Read the full review of the 3D Systems Cube 3.

Dong Ngo/CNET

XYZprinting Da Vinci 1.0 AiO

The Da Vinci 1.0 AiO is my most favorite 3d printer, and not just because it’s quite inexpensive — at $800 (available in the UK for £649; pricing and availability for Australia will be announced later), it’s by far the cheapest full-featured all-in-one 3D printer on the market. I like it because it works consistently well right out of the box, without requiring you to manually calibrate its build platform (it arrives precalibrated). It can print very large objects and is the first 3D printer that can do 3D scanning, too. If you can deal with its rather large physical size, this is the second-best deal on the market so far, after the Da Vinci Jr. above.

Read the full review of the XYZprinting Da Vinci 1.0 AiO.

Josh Miller/CNET

Ultimaker 2

There’s a lot to like about the Ultimaker 2. This is the most compact 3D printer I’ve seen that yet has a large build platform. The machine is very well built, has a great design, and it looks good, too. Unfortunately, you have to manually calibrate it, and at $2,500 (that price price converts to about £1,600 and AU$3,000), it’s just too expensive.

Read the full review of the Ultimaker 2

Editors’ note: This article was originally published on February 6, 2015, and will be regularly updated as new printers become available. It was most recently updated on January 13, 2016.