ACS Nano

Options for a wearable, portable charging solution include a jacket with solar panels stuck on the back and shoes that collect kinetic energy — but a new type of fabric taps into something we usually find undesirable — static electricity.

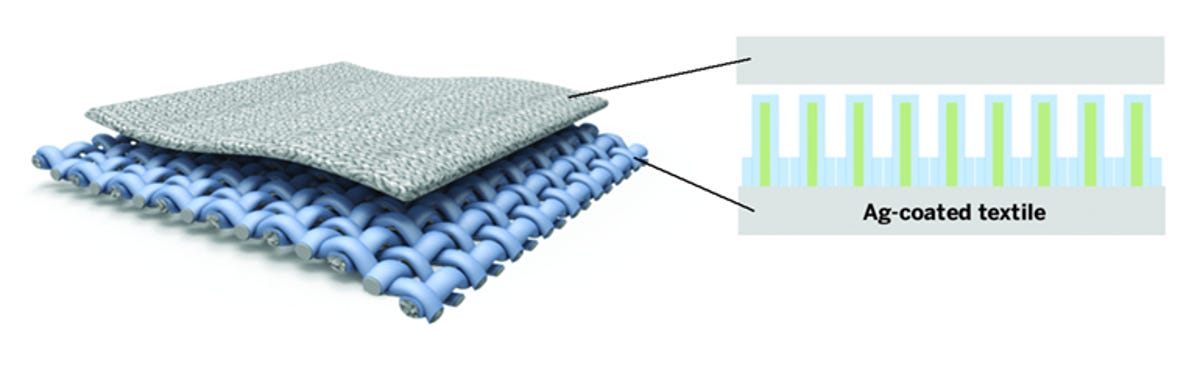

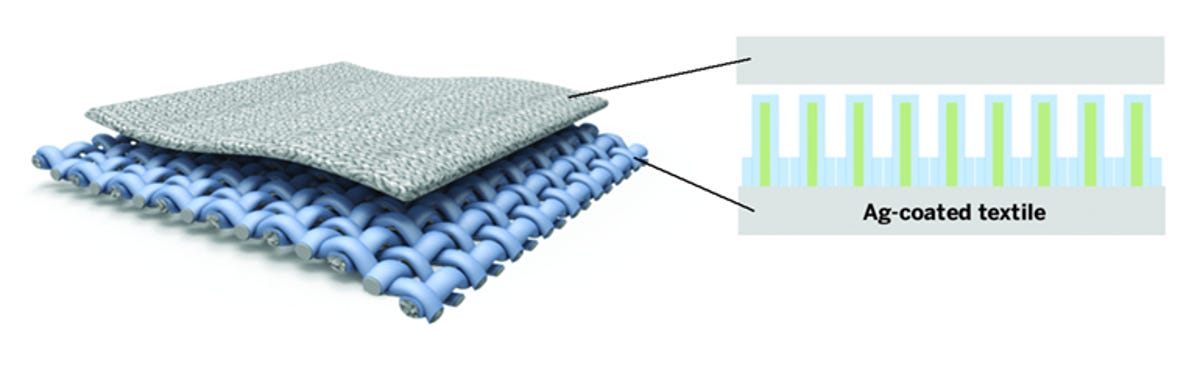

Created by a team led by materials scientist Sang-Woo Kim at Sungkyunkwan University in South Korea, the material consists of a two layers of fabric, one of silver-coated fibres, the other containing zinx oxide nanorods coated with polydimethylsiloxane. The layers rub together when they move, which can be triggered by natural, day-to-day motions.

Related articles

- Tommy Hilfiger launches solar power jackets to charge your phone

- Carbon puts a portable solar charger on your wrist

- Get smart: Charge your phone while walking in this shoe

This produces something called the triboelectric effect, which is also responsible for the static electricity caused when, say, you rub a balloon on your hair, or silk on glass. When the two materials rub together, electrons transfer between the surfaces, which creates a positive charge one one side and a negative charge on the other.

When the materials are separated, this creates a small electric current — something you might have felt arcing from your hand when you reach for a metal doorknob after walking on carpet on a windy day.

Not every pair of materials produces this effect, or walking down the street would be a different experience: part of the work for Professor Kim and his team involved finding the best pair of materials for producing optimum levels of static charge — the silver and the nanopatterned polydimethylsiloxane, a type of silicone. The 100-nm zinc oxide nanorods increase the contact area, which leads to greater friction and therefore greater power output.

ACS Nano

According to the paper, a four-centimetre square piece of silver and nanopatterned polydimethylsiloxane cloth was able to produce an output voltage and current of around 120V and 65 μA respectively, while the non-nanopatterned polydimethylsiloxane produced voltage and current of 30V and 20 μA when paired with the silver under the same compressive force of 10 kgf.

When four layers were stacked, this produced an output of 170V and 120 μA — and, over 12,000 cycles, there were no significant differences in the output voltages of the multi-layered fabric.

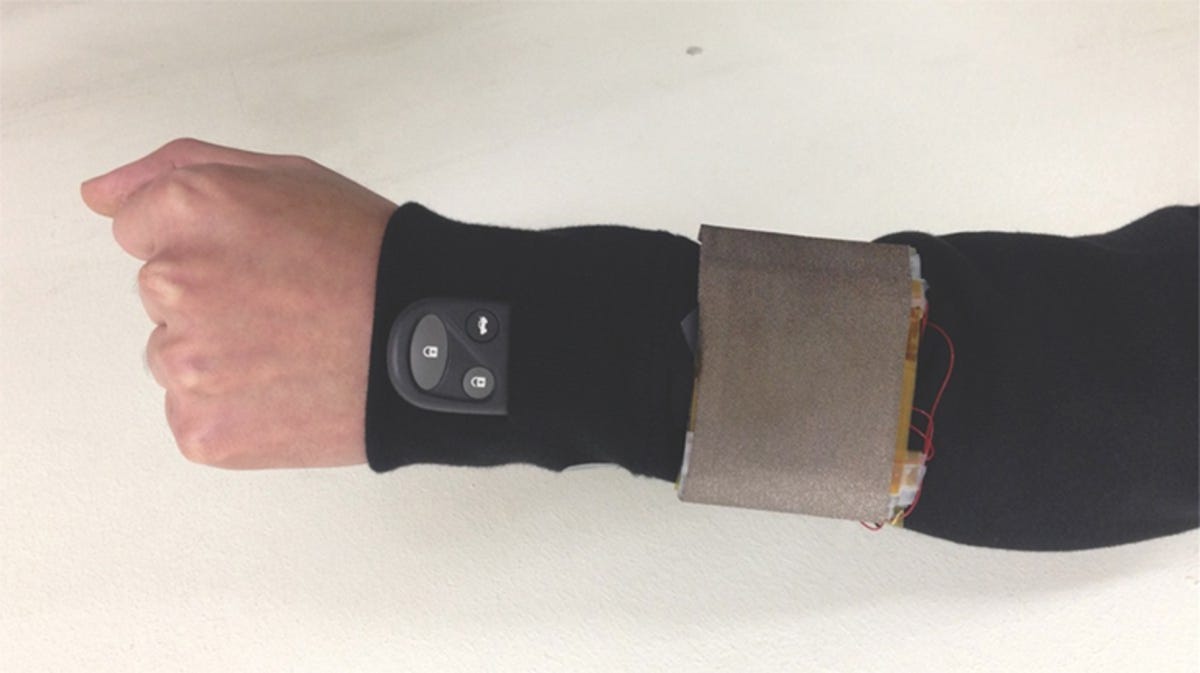

Attached to a jacket sleeve, the cloth was then used to successfully power six embedded LEDs, a small LCD and a keyless car remote inside the jacket. When the wearer moved his wrist, this produced enough power — without the help of any external power sources — to turn each of these devices on, although only one at a time.

Obviously it has its limitations. It could not, in its current state, power a smartphone, although perhaps paired with a battery pack, it could store the power generated for emergencies. One could also not wear an entire garment made out of the material — a silicone jacket would get rather sweaty.